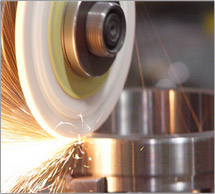

Surface Grinding Services

(click on thumbnail to enlarge)

Dynamic Precision Tool & Manufacturing has been providing high level machining and grinding for our clients out of our facility in Troy, Michigan since 1982. When it comes to surface grinding, Dynamic Precision is a trusted resource to provide precision grinding services of very high quality. Our facility has CNC controlled and manual grinders for flat, form, radius, and precision surface grinding of a variety of parts. Some of these include special machine parts, gages, die details to aerospace parts.

We grind a variety of standard and exotic metals including brass, bronze, steel, copper, aluminum, stainless steel, nickel alloys, carbide, nitronic 60, Inconel, Hastelloy, and Monel. Our equipment grinds parts up to 40” long and 20” wide, with a surface finish to 8 µin. We surface-grind our products to exact precision, with parallelism, flatness, perpendicularity/squareness, and tolerance all ground to within ± .0001”. Some of the applications for our precision-ground components include assemblies, critical parts, precision components, and production parts for various high tech industries, such as the aerospace, defense, automotive, medical, technology, and oil field industries.

We turn around orders with typical lead times of one week, with rush services available. To learn more about this precision surface grinding service, see the following table, or contact us directly.

Surface Grinding Capabilities:

- Surface Grinding Process

-

- Flat

Form - Radius

Precision

- Flat

- Automation Capabilities

- CNC

Manual

- Part Types

-

- Special Machine Parts

Gages - Die Details

Aerospace Parts

- Special Machine Parts

- Materials (Metals) (Exotic Metals)

-

- Steel

Tool Steel

Stainless Steel

Aluminum

Brass

Bronze

Copper

Titanium

Tungsten - Molybdenum

Nitronic 60

Nickel Alloys

Carbide

Non-Magnetic

Inconel

Hastelloy

Monel

- Steel

- Part Length

- Up to 40 in

- Part Width

- Up to 20 in

- Parallelism

- ± .0001 in

- Flatness

- ± .0001 in

- Perpendicularity/Squareness

- ± .0001 in

- Tolerance

- ± .0001 in

- Surface Finish

- 8 µin

- Inspection

-

- Coordinate Measuring Machine (CMM)

Height Gages

Optical Comparators - Profilometer

Gage Blocks

Surface Plates

- Coordinate Measuring Machine (CMM)

- Testing

- Surface Roughness

Hardness

- Quality Documentation

- Blueprints

Job Router

- Additional Services

- Design

Precision Gages

- Production Volume

- Prototype to Short Runs

- Typical Lead Time

-

- 1 week

1 day (Possible)

Rush Services Available - Quick Turnaround

Short Deliveries

- 1 week

Additional Information

- Industry Focus

-

- Aerospace

Defense

Automotive - Medical

Technology

Oil Field

- Aerospace

- Intended Applications

-

- Assemblies

Critical Parts - Precision Components

Production Parts

- Assemblies

- Industry Standards

- ISO 9001:2008 Certified

ASTM

AISI

- Efficiency

- Lights Out Manufacturing

- File Formats

-

- CAD/CAM System

MasterCAM

DXF - IGES

STEP

DWG

- CAD/CAM System

Print This Page

Print This Page